Bradken’s foundry was a ferrous metals foundry located in Hillside Dunedin, it occupied the ex Kiwi Rail foundry which had been in operation since 1875. Bradken closed the site in late 2020 and Skylarc were assigned to work with the remaining Bradken team to sell down the assets onsite and facilitate their decommissioning and removal.

The Challenge

Bradken’s site was sprawling and extremely challenging, spread over 1.5 hectares and occupying numerous buildings ranging from the huge foundry building to office blocks and everything in between. Assets included a range of precision metalworking and woodworking machinery found in the pattern shop, the aftercast area which contained welding, grinding and metal treatment equipment, the main foundry where a wide range of lifting equipment along with furnaces and hot metal working equipment and the yards around the buildings which contained everything from an old railway wagon to hundreds of steel bins of all shapes and sizes.

Ensuring a safe process was critical in such a challenging environment where major decommissioning of large pieces of plant and machinery needed to be done in a planned manner by suitably trained and qualified personnel with the appropriate job safety analysis completed and signed off by Bradken. Time pressure was also a factor with Skylarc starting onsite on November the 1st and the site needing to be cleared by the end of January 2021.

The Process

The auction setup was split into two periods, with Bradken continuing to operate on the site until the 1st of December in the Aftercast area of the foundry where castings were finished and treated prior to dispatch to customers. Skylarc began preparation in the patternshop, maintenance areas and main foundry with the aftercast area to be started as soon as Bradken’s completed their final customer orders. Over 1500 items were described, photographed and tested in preparation for listing the auction. Working closely with Bradkens management and Health and Safety personnel, preliminary decommissioning of overhead cranes, disconnection of electrical/gas and pneumatic energy sources was organised to ensure a minimum risk environment when final collection and dispatch occurred. Plant and equipment located in difficult to access areas like mezzanine floors was relocated to easily accessible areas to speed up collection and minimise risks. The auction was listed for 10 days closing over three nights with lots evenly spread between 6pm and 10pm, Trade Me’s busiest time. This enabled potential buyers to bid on multiple lots without having significant overlap between each lot. To ensure a safe and controlled removal process, three collection phases were run, firstly for small items collected by hand, secondly for medium sized machines once all of the small items were gone and finally for large machinery that required heavy lift equipment and specialist decommissioning teams.

Marketing

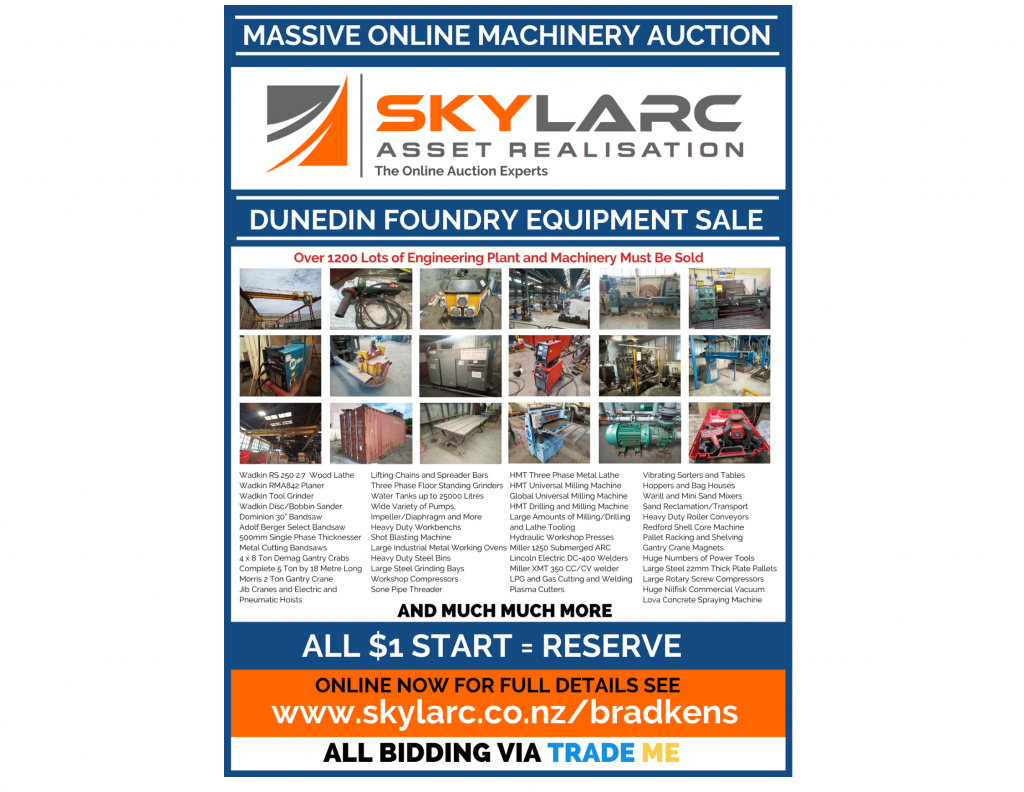

A comprehensive plan to sell all assets via an online Trade Me event was produced backed by a detailed marketing plan incorporating display advertising on Trade Me, a targeted Facebook campaign, industry email outs, and advertising in the major Dunedin papers. A phone campaign contacting engineers and foundries throughout New Zealand was also run during the week the auction was online.

Results

The large number of high quality lots bought a very large online audience and some impressive financial results. The site was cleared on schedule and all Skylarc’s activities onsite were completed on time.